Versatile and Reliable Equipment for Efficient Magnetic Particle Testing

Yokes are essential tools in Magnetic Particle Inspection (MPI), based on the electromagnetic principle. When an electric current passes through a coil or solenoid wrapped around a laminated magnetic core, it generates a magnetic field. This magnetic field is used to detect surface cracks and discontinuities by creating a flux on the area to be tested. The Yoke applies magnetic flux to the inspected surface, revealing cracks that are orthogonal (±45°) to the magnetic field direction. With the use of magnetic powder (wet or dry), the magnetic field highlights defects, ensuring the highest level of inspection accuracy.

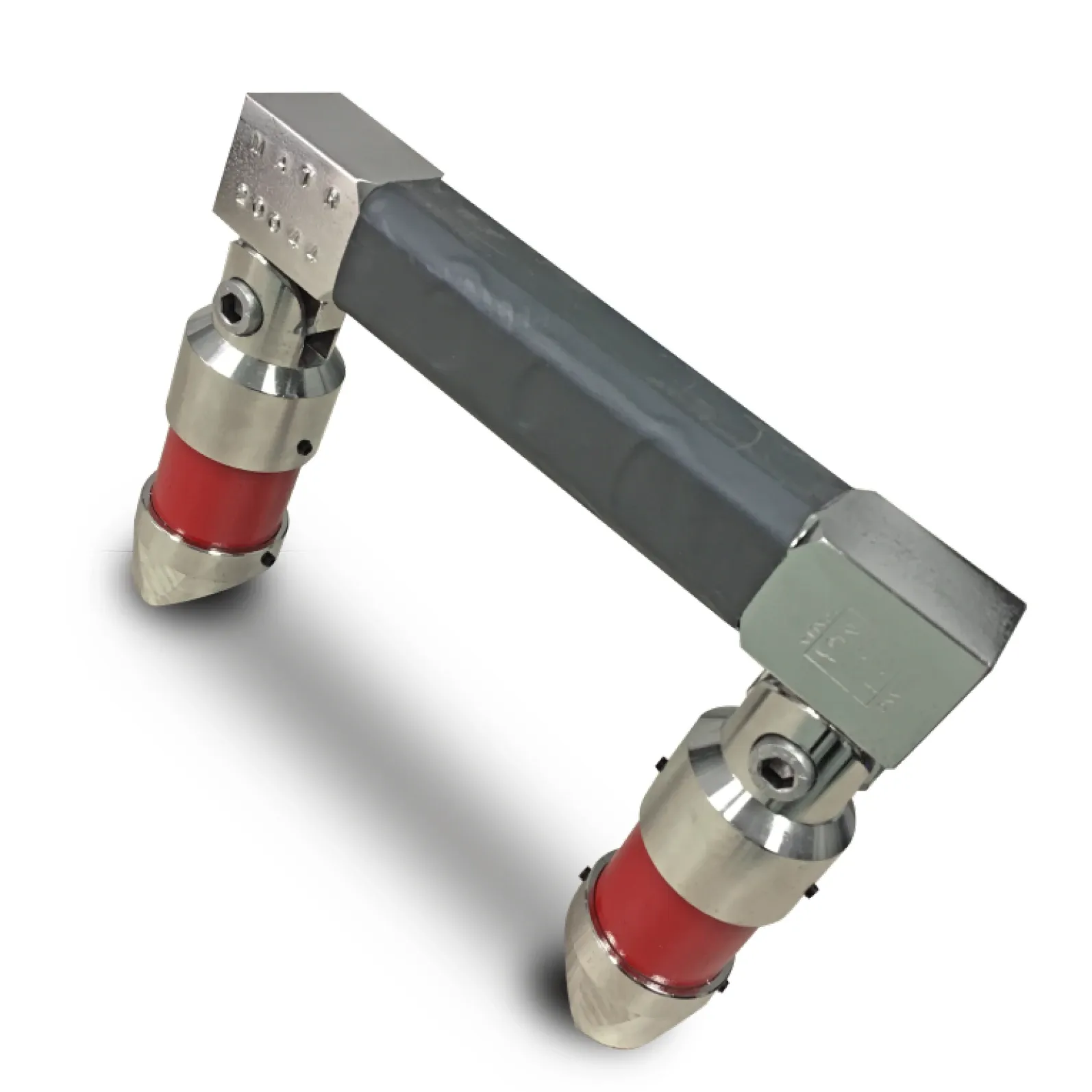

CGM CIGIEMME S.P.A. offers a comprehensive range of Yokes, including models powered by 220 V, 48 V, and battery-operated versions. The Yokes are CE marked and built according to industry standards, ensuring reliability, efficiency, and ease of use in various testing conditions.

Models Available:

- Yoke 230 V ref. 58.13 (AC/DC powered)

- Yoke 48 V ref. 58.15 (Battery/DC powered)

- Permanent Magnet Yoke ref. 54.6/54.10 (DC powered)

Applications:

- Ideal for inspecting welded joints in industries like aerospace, automotive, and construction.

- Detects cracks in castings and forgings for the automotive, energy, and manufacturing sectors.

- Perfect for testing ferromagnetic components for surface defects.

- Suitable for on-site and field inspections due to its portability and ease of operation.