Customized Solutions for Reliable and Efficient Magnetic Particle Inspection

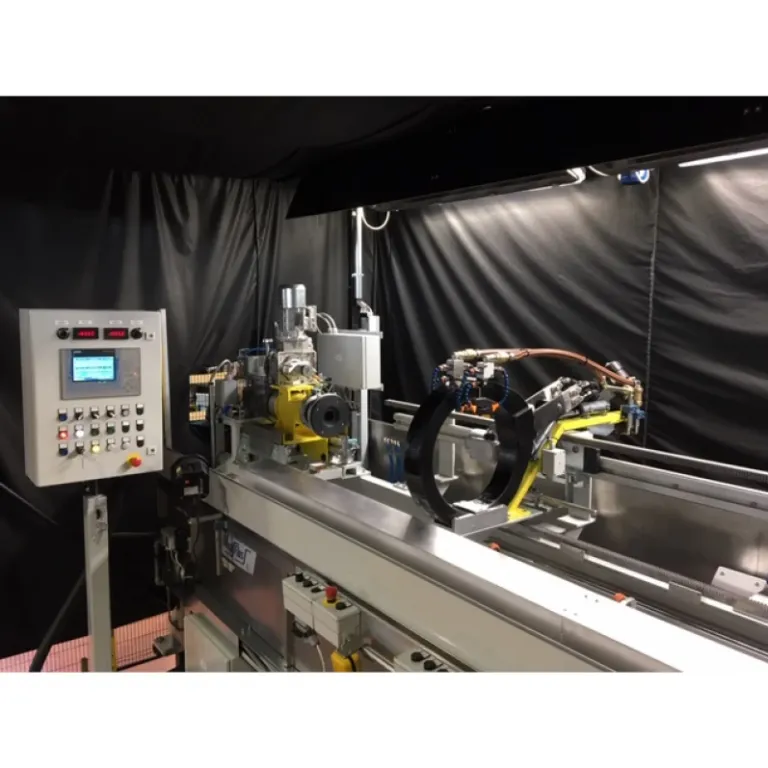

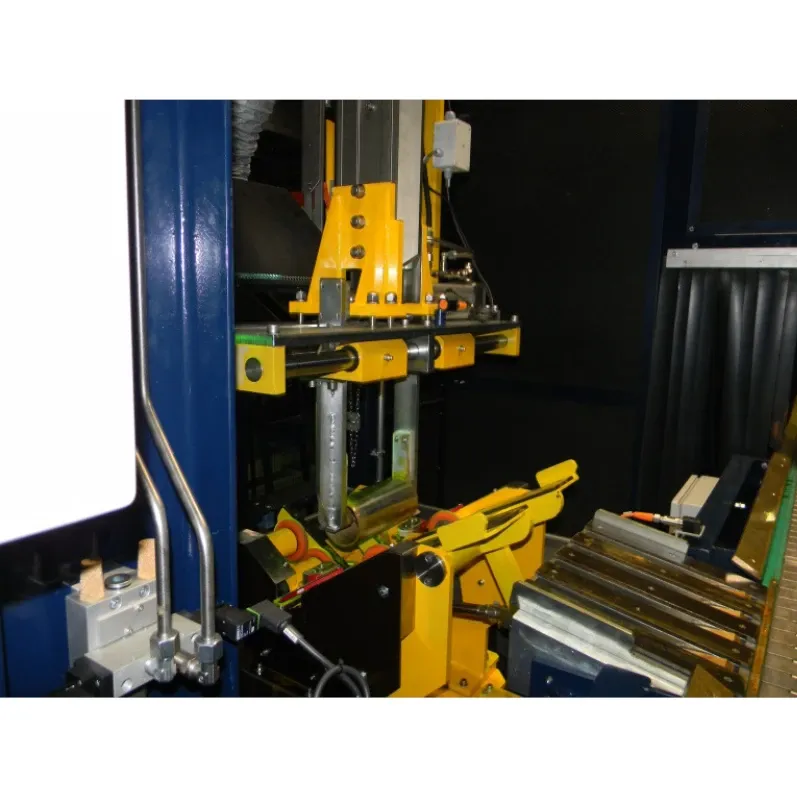

CGM’s Magnetic Particle Inspection (MPI) systems are renowned for their exceptional reliability, durability, and efficiency in detecting surface defects. Each MPI system is designed with precision to meet the specific requirements of your inspection tasks, with customized solutions tailored to the geometry and characteristics of the component being tested. From semi-automated to fully automated systems, CGM offers a comprehensive range of stand-alone and in-line inspection solutions to suit various industrial applications.

These magnetic particle testing systems provide superior performance and high-quality results, ensuring accurate defect detection and efficient testing processes. Whether you require standard bench units or specialized de-magnetizing options, CGM has the ideal solution for your needs. Contact us to explore the variety of options available, including customizable features designed to optimize your MPI operations.

Applications:

- Inspection of components such as engine blocks, gears, and other critical parts for surface defects.

Used for inspecting turbine blades, structural components, and other high-precision parts. - Ideal for detecting surface defects in a wide range of materials, ensuring the integrity of products and parts.

- Perfect for integration into production lines where continuous, automated testing is required.