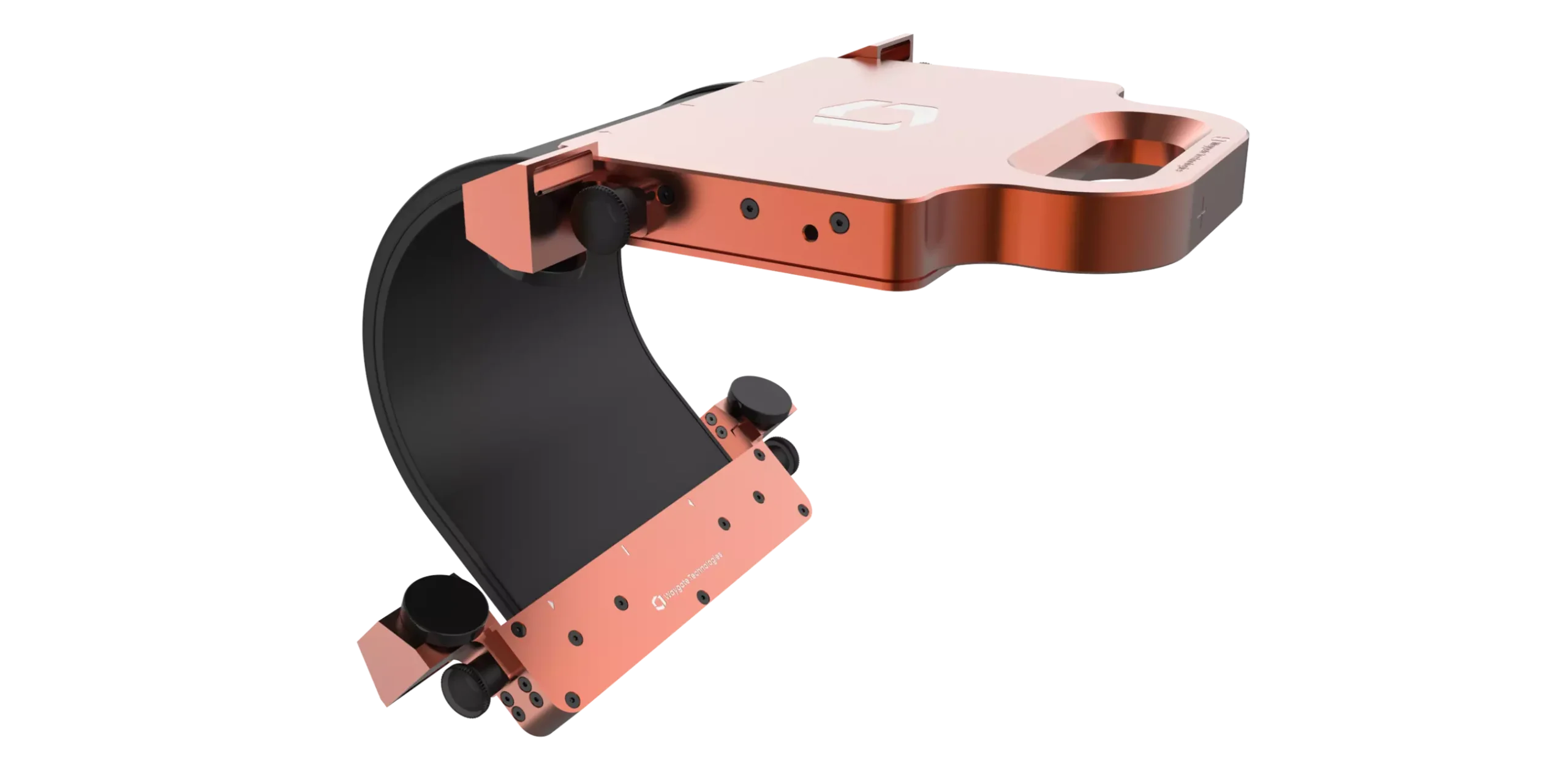

High-Quality Bendable Detectors Designed for Efficiency and Robustness

The DXR Flex 1025 and DXR Flex 1043 detectors redefine portable radiography by offering flexibility, easy handling, and fast imaging for a variety of industrial applications. With cutting-edge technology and rugged design, these detectors deliver exceptional image quality, optimised for non-destructive testing (NDT) in challenging environments. Whether you are inspecting pipelines, vessels, or complex weldments, the DXR Flex family is built to meet your specific needs.

Applications:

- Oil and gas applications focus on pipeline inspections, including welds, crack detection, and fabrication in spools, vessels, and tanks.

- Aerospace and space sectors ensure safety and reliability with weld inspections and critical component evaluations.

- Power generation excels in inspecting piping, tanks, and structural components in power plants.

- Industrial and defense applications cater to military equipment checks and inspections in the pulp and paper industry to ensure integrity and safety.