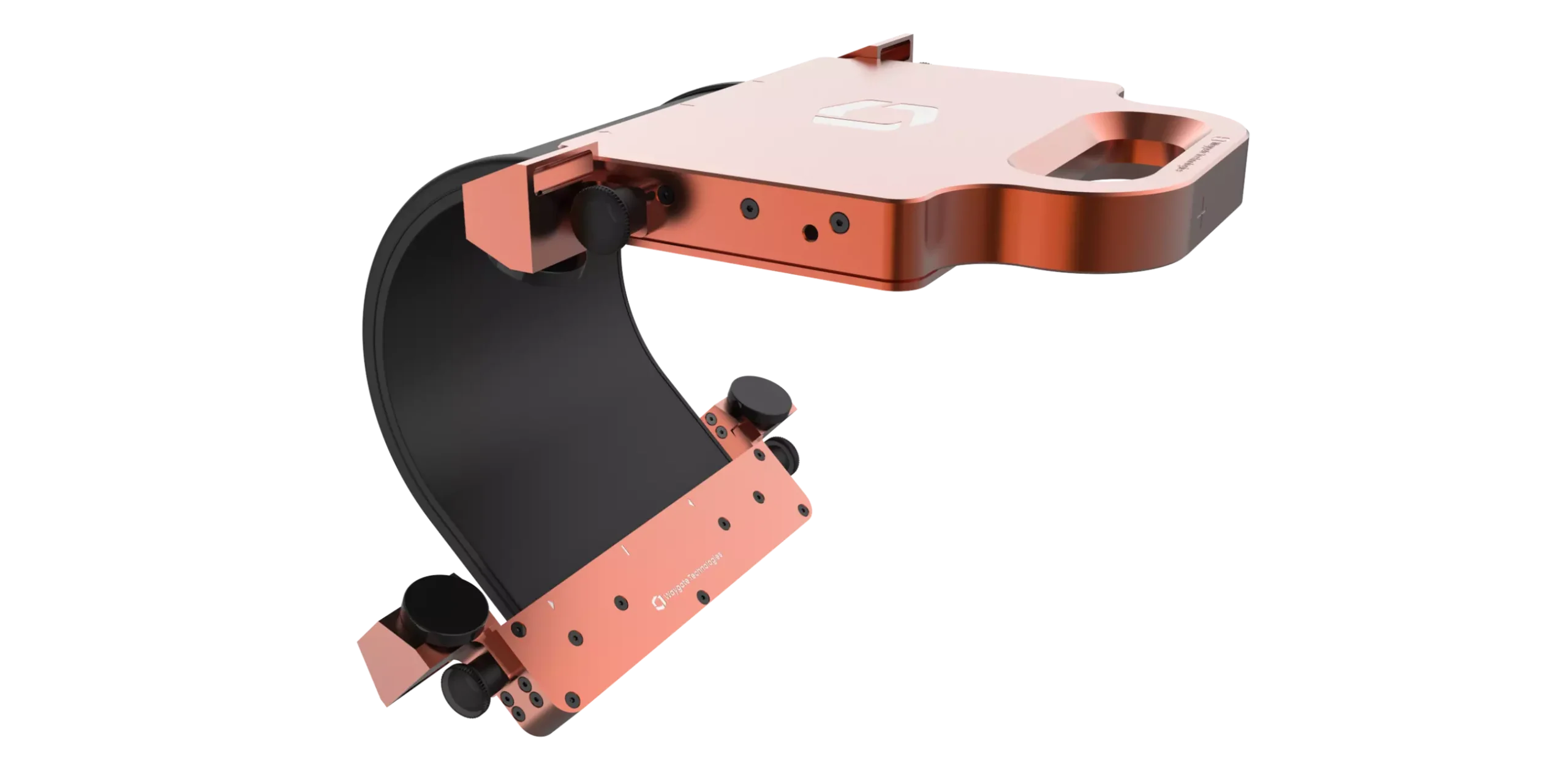

Digital X-ray detector inspection solution

for cabinet integration

As the demand for faster and more efficient production grows in the market, we at Labquip NDT are proud to partner with Waygate Technologies to address these challenges by bringing you the latest innovations in industrial inspections.

With the new DXR 100S/200S 41M solutions, you can now achieve higher resolutions and consistent image quality that lasts longer across various applications. This dynamic 41 detector technology is a standalone package designed for cabinet integration that allows the inspection of larger components as compared to other DDA-based solutions.

Applications:

- Power generation involves inspecting welds, turbine blades, and critical components to ensure structural integrity and safety.

- Aerospace and automotive sectors conduct high-resolution inspections of castings, drivetrain components, blades, wings, and electrical boards for quality control and defect detection.

- Defense and medical industries rely on precise inspections in defense systems and medical equipment manufacturing to ensure safety and compliance.

- Industrial manufacturing focuses on evaluating suspension components, electrical boards, and other industrial parts to maintain product quality and streamline production.