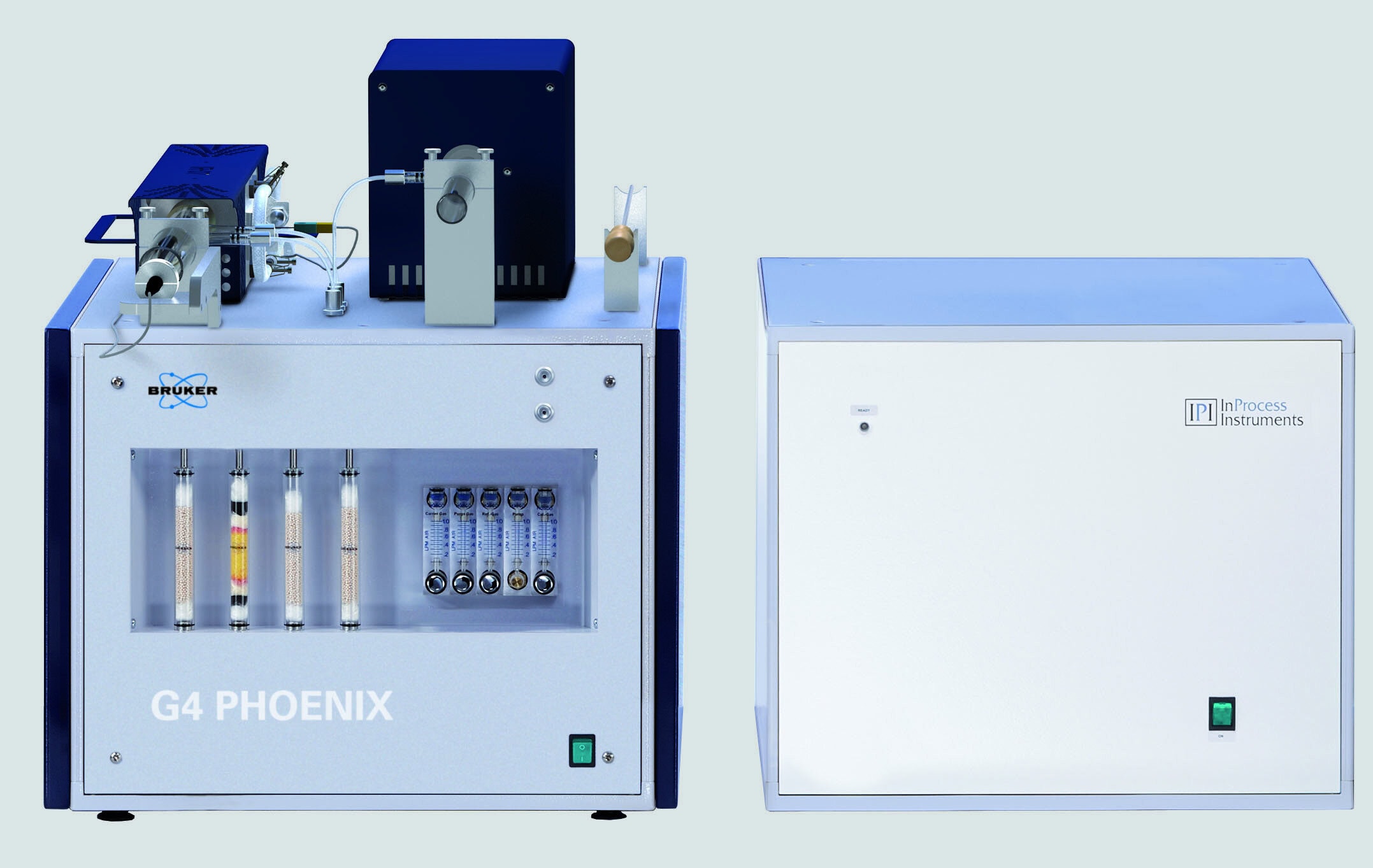

Advanced Diffusible Hydrogen Analysis to Prevent Embrittlement and Cracking with Fast, Accurate Results

The G4 PHOENIX DH analyser by Bruker ensures rapid, precise diffusible hydrogen measurements to mitigate embrittlement, hydrogen-induced cracking, and other structural failures. Its advanced carrier gas warm extraction method delivers results in less than 30 minutes, making it the ultimate tool for post-welding tests and material quality assurance.

Applications:

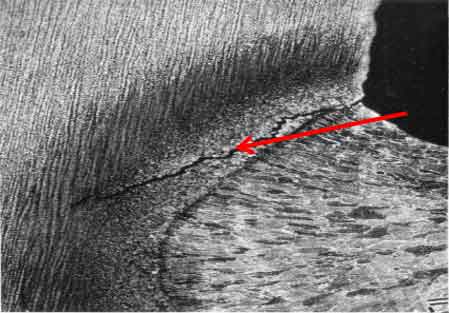

- Welding Industry prevents hydrogen-induced cracking by measuring diffusible hydrogen levels post-welding.

- High-strength steels reduce embrittlement risks by analysing hydrogen content in advanced alloys.

- Material research and alloy development utilise thermal desorption mass spectrometry (TDMS) to study hydrogen trapping and advance alloy innovation.

- Automotive and aerospace ensure hydrogen resistance in high-performance materials and structural components.